- Home

- Techniques

- EDM

- Micro drilling

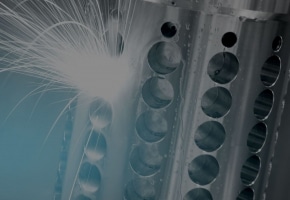

MICRO DRILLING

Micro drilling is the drilling of round holes with small diameters. Ter Hoek offers a choice between laser drilling or hole-drilling EDM depending on the material and the desired diameter and depth. This allows customers to quickly and accurately drill holes in a variety of materials, from steel to carbide, copper, and aluminum, and from semiconductors to insulators.

Ter Hoek supplies micro drilling techniques to a wide range of satisfied customers throughout Europe. In our manufacturing facility in Rijssen, the best professionals work passionately on the continuous improvement of our services. Every day, we develop new and innovative solutions for our customers in the high-tech manufacturing industry.

Micro drilling is the drilling of round holes with small diameters. Ter Hoek offers a choice between laser drilling or hole-drilling EDM depending on the material and the desired diameter and depth. This allows customers to quickly and accurately drill holes in a variety of materials, from steel to carbide, copper, and aluminum, and from semiconductors to insulators.

Ter Hoek supplies micro drilling techniques to a wide range of satisfied customers throughout Europe. In our manufacturing facility in Rijssen, the best professionals work passionately on the continuous improvement of our services. Every day, we develop new and innovative solutions for our customers in the high-tech manufacturing industry.

What is micro drilling?

Micro drilling offers a unique combination of extreme accuracy and high manufacturing speed. The technique is particularly suitable for drilling small holes with very precise tolerances (down to 1 micron). For this purpose, Ter Hoek uses a solid, round, rotating electrode to drill a hole in various materials using spark discharge.

On the other hand, the laser drilling variant is ideal for creating right-angled cutting surfaces and three-dimensional shapes. A micro-laser beam with a diameter of 30 to 80 microns is surrounded by a minuscule water jet, which reflects outgoing beams while simultaneously lowering the temperature of the machined hole. This creates near-perfect shapes.

What are the advantages of micro drilling?

There are many advantages to micro drilling. Just think of the high precision (drilling to an accuracy of 1 micron) and manufacturing speed. When choosing laser drilling technology for a project, the three-dimensional possibilities and diverse application areas draw your attention. There is a high demand for micro-drilling technology that combines extreme precision with high process reliability in sectors such as the energy industry, the medical world, and the diamond and metal processing industry.

Why micro drilling by Ter Hoek?

Micro drilling by Ter Hoek is an excellent choice for customers who have strict quality requirements. With more than 25 years of experience in the field and as an AS9100 certified specialist, we know the world of precision components better than anyone. In our climate-controlled manufacturing facility, passionate professionals are developing tomorrow’s solutions.

In a precision mechanical process such as micro drilling, the advice, and support regarding the process is of the utmost importance. Ter Hoek excels in this area and offers custom advice as a standard part of its service. Over the years, we have grown from a service provider to a full-fledged problem solver and knowledge partner.

What are the costs of micro drilling?

The costs for micro drilling can vary depending on various aspects. The customer’s requirements and the batch size determine the price, of course, but elements such as material choice, shape, and dimensions also influence the final costs. After detailing all the requirements, the Ter Hoek consultants always succeed in providing an attractive quote.

Are you curious about the exact costs for your project, or would you like assistance in choosing a micro drilling technology? Our specialists are happy to explain the possibilities of micro drilling in detail and support you in making a cost-effective decision. Contact us now at info@terhoek.com or call us on 0548 – 54 08 07.

MACHINING EXAMPLES FOR MICRO DRILLING

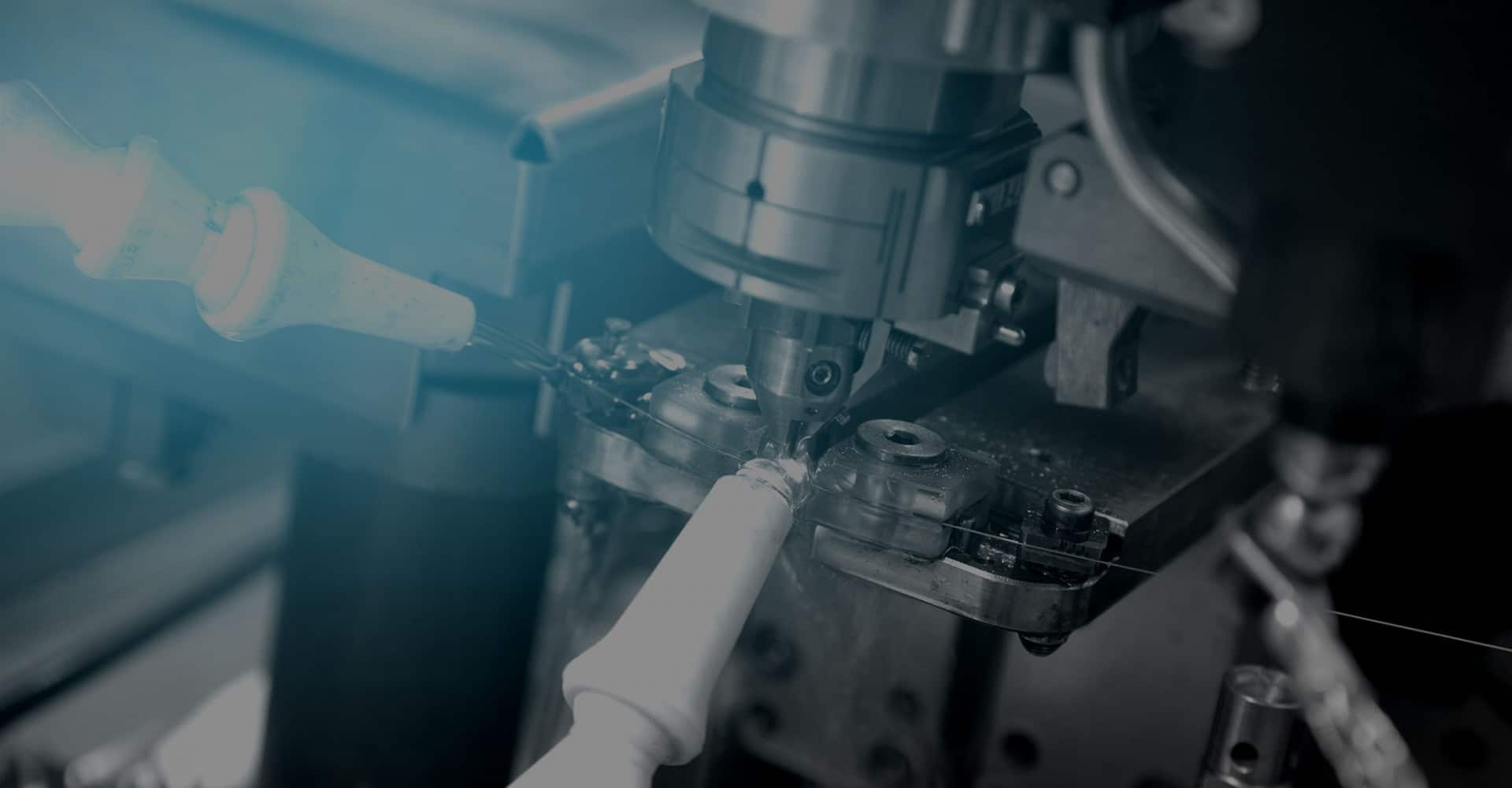

INNOVATIVE AND ORGANIZED

The advanced machinery in our climate-controlled manufacturing facility gives our team the space to do what we do best: deliver innovative and high-quality solutions, regardless of shape, size, material, or batch size. In the process, we maintain short lead times and a tight organization.