- Home

- Techniques

- EDM

- Micro drilling

- Hole-drilling EDM

HOLE-DRILLING EDM

Hole-drilling EDM is a machining method based on spark erosion and is therefore also called spark machining. The technique is used to quickly and accurately create holes in a workpiece. Examples include starter holes for further machining or air, cooling, and supply ducts.

Over the years, Ter Hoek has built a reputation as a leading specialist in spark machining. With high-quality machinery and based on long-standing knowledge and expertise, we develop new custom solutions for customers in the high-tech manufacturing industry every day.

Hole-drilling EDM is a machining method based on spark erosion and is therefore also called spark machining. The technique is used to quickly and accurately create holes in a workpiece. Examples include starter holes for further machining or air, cooling, and supply ducts.

Over the years, Ter Hoek has built a reputation as a leading specialist in spark machining. With high-quality machinery and based on long-standing knowledge and expertise, we develop new custom solutions for customers in the high-tech manufacturing industry every day.

What is hole-drilling EDM or spark machining?

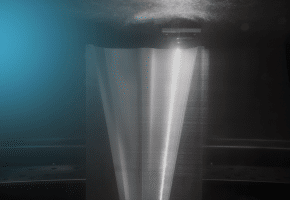

Hole-drilling EDM uses a hollow tubular electrode to create holes in a workpiece. The rotating tubular electrode uses spark discharge to drill a hole in a variety of materials such as iron alloys (e.g., steel), aluminum, copper, and carbide. An EDM drill operates completely computer-driven and therefore works very accurately.

During spark machining, rinse water is injected through the electrode at relatively high pressure. The residue flushes upward along the outside of the electrode. This makes it possible to create tiny and deep holes. Holes with a diameter of 1 millimeter in material 600 mm thick are one of the various possibilities at Ter Hoek.

Advantages of hole-drilling EDM

Hole-drilling EDM is particularly suitable for creating starter holes in a workpiece. This is also referred to as start hole EDM drilling and is often considered the first step in a further machining and development process. For example, starter holes are created, which are then used in wire EDM as through holes for contour cutting.

But EDM is also very suitable for making cooling or air ducts and supply-channel holes for oil or liquids. The machining possibilities of different types of (hard) metals with high speed and precision make this technique an excellent choice for (small) series and also widely applicable for various technical purposes.

EDM Drilling: A Smart Alternative to Laser Micro Jet Technology

While laser micro drilling and laser micro hole drilling offer high precision, they can sometimes cause thermal stress in delicate materials. In contrast, EDM drilling provides a non-contact solution that avoids heat damage, making it ideal for microholes in sensitive applications. Unlike the laser micro drilling process, EDM hole drilling ensures smooth, accurate results without micro-cracks. Whether you need laser drilling micro holes or EDM precision hole drilling, we offer expert guidance to determine the best method for your needs.

Why spark machining at Ter Hoek?

High-Precision Micro Drilling & EDM Hole Drilling Solutions:

For industries requiring ultra-precise micro drilling, we offer cutting-edge solutions using advanced EDM drilling and micro drilling machines. Our expertise in micro hole drilling ensures accuracy and efficiency for even the most complex projects.

Expertise in EDM Hole Drilling:

With our specialized EDM drill technology, we provide high-speed and accurate hole drilling EDM services. Whether you need fast hole drilling EDM or EDM precision hole drilling, our state-of-the-art equipment guarantees consistent, high-quality results.

Microhole Drilling for Small Hole Manufacturing:

Our microdrilling solutions are ideal for small hole manufacturing across various industries. We specialize in small hole drilling, ensuring precise microholes in metals and other materials. From EDM micro drilling to fast hole EDM drilling, our services deliver exceptional precision and efficiency.

If you're looking for reliable EDM hole drilling and micro drilling EDM services, contact us today to discuss your project requirements!

What are the costs for EDM drilling?

Do you want to drill fast, small or deep? Ter Hoek offers virtually unlimited possibilities in the field of spark machining. The costs for our high-quality services might pleasantly surprise you. Because EDM drilling is a technique that is mainly unmanned, it is an affordable option compared to some alternatives.

Of course, the final costing of spark machining depends on several factors. For example, you have to consider the desired size, shape, and material you want to use. The batch size and possible additional requirements also influence the price. Regardless, Ter Hoek always guarantees you a very competitive quote.

Would you like to know exactly what we can do for you in terms of hole-drilling EDM? Then do not hesitate to contact us for a custom quote. Our specialists will be happy to help you find a suitable solution and help you work out the costs. Call us on 0548 – 54 08 07 or send an e-mail to info@terhoek.com.